Ammonia Production Process Pdf

The proportion of carbon of biogenic origin is usually in the range of 33 to 50 percent. Generation of H 2 by water electrolysis equation followed by the conventional HaberBosch process at.

Introduction To Ammonia Production Aiche

Valera-Medina in Techno-Economic Challenges of Green Ammonia as an Energy Vector 2021 Production.

. Ammonia NH 3 is a globally important commodity for fertilizer production but its synthesis by the Haber-Bosch process causes substantial emissions of carbon dioxideAlternative zero-carbon emission NH 3 synthesis methods being explored include the promising electrochemical lithium-mediated nitrogen reduction reaction which has. A much wider application of the tech-nology is desirable in the current endeavours towards sustainable development and renewable energy production. Here are some NDSU Extension publications that can help you and your family during the COVID-19 pandemic.

The HaberBosch process for synthetic ammonia production has been one of the most impactful inventions in human history because it made bread from air thereby facilitating a dramatic increase in the world population 13The HaberBosch process. Climate Action - Technologies to reduce. However the reaction.

Due to the important role of ammonia as a fertilizer in the agricultural industry and its promising prospects as an energy carrier many studies have recently attempted to find the most environmentally benign energy efficient and economically viable production process for ammonia synthesis. To execute the process. CO2 is widely used in food production and the move by CF is expected.

This leaves three plausible scenarios for the potential production of renewable ammonia. As mentioned hydrogen produced from ammonia is used in fuel cells engines and turbines. Production of carbon dioxide a by-product of the ammonia production process will cease until the ammonia plant is restarted.

This page was last edited on 1 July 2022 at 0945 UTC. Process with a low energy requirement used to convert organic material from a wide range of wastewater types solid wastes and biomass into methane. The climate-relevant CO2 emissions from waste incineration are determined by the.

Electrocatalytic recycling of waste nitrate NO3 to valuable ammonia NH3 at ambient conditions is a green and appealing alternative to the HaberBosch process. The future of a carbon-free society relies on the alignment of the intermittent production of renewable energy with our continuous and increasing energy demands. However adoption of ammonia as a hydrogen source especially for transportable devices and automobiles has been limited largely because of the absence of an efficient process for decomposing ammonia to hydrogen and nitrogen 1618 27Overcoming this issue will.

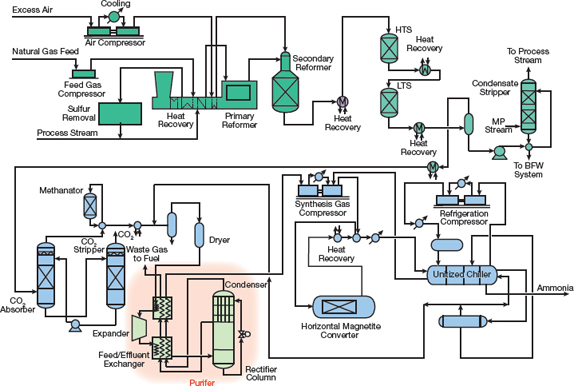

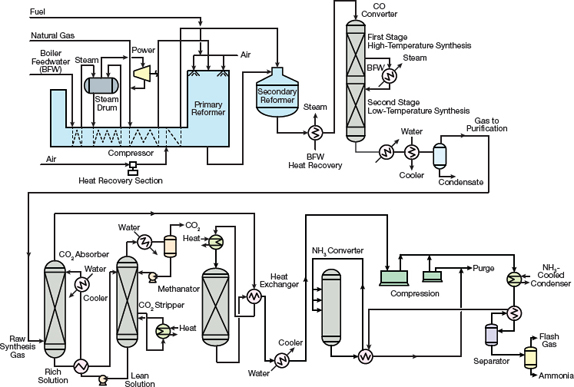

It is interesting to compare this energy consumption to the catalysts from Table 1 especially the strained Ru nanoclusters catalyst as Yu et al. Ammonia production process plant flow sheet in brief with three controls. Ammonia production depends on plentiful supplies of energy.

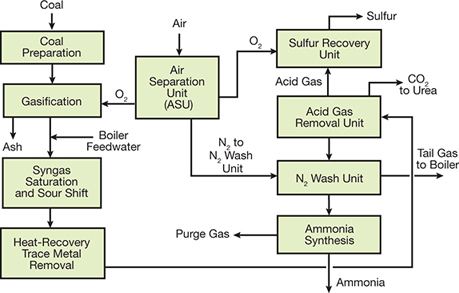

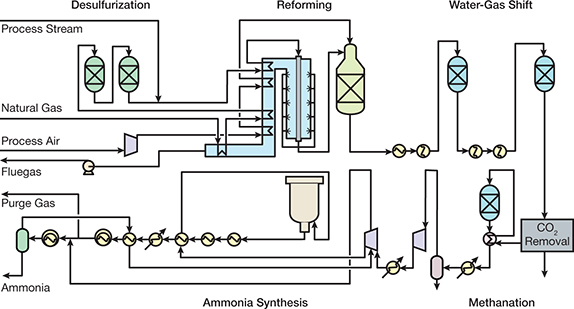

The decarbonisation of ammonia production 12 11 Current ammonia production process brown ammonia 12 12 Blue ammonia production using blue hydrogen from steam methane reforming SMR with carbon capture and storage CCS 14 13 Green ammonia production using green hydrogen from water electrolysis 14 131 Research opportunities 16. The incineration of 1 Mg of municipal waste in MSW incinerators is associated with the productionrelease of about 07 to 12 Mg of carbon dioxide CO2 output. Ammonia is a compound of nitrogen and hydrogen with the formula NH 3A stable binary hydride and the simplest pnictogen hydride ammonia is a colourless gas with a distinct pungent smell.

In the 1980s several projects. Lawrence Berkeley National Laboratory Scroll down to page 39 of 40 PDF pages for a list of the ammonia plants in the United. The most commonly utilized ammonia production method is the Haber.

Nitrate electrocatalytic reduction NO 3 RR for ammonia production is a promising strategy to close the N-cycle from nitration contamination as well as an alternative to the HaberBosch process with less energy consumption and carbon dioxide release. The global ammonia market is projected to grow from 7198 billion in 2021 to 11093 billion in 2028 at a. Report an electrocatalytic rate for ammonia production of 556 mol g cat 1 h 1 for 100 h which even outperforms the Haber-Bosch process.

For these fertilizers is dependent upon the demand for oilseeds and grains crops that drives the overall fertilizer production. Most of the ammonia produced is used in the agriculture industry as a. However current long-term stability of NO 3 RR catalysts is usually tens of hours far from the.

Biologically it is a common nitrogenous waste particularly among aquatic organisms and it contributes significantly to the nutritional needs of terrestrial organisms by serving as a. Long-term energy storage in molecules with high energy content and density such as ammonia can act as a buffer versus short-term storage eg. 6 For the production of 1 kg ammonia the strained Ru nanoclusters catalyst.

Ammonia Industrial Efficiency Technology Measures

Introduction To Ammonia Production Aiche

No comments for "Ammonia Production Process Pdf"

Post a Comment